Address

Miami, FL

Work Hours

Monday to Friday: 9 AM - 5 PM

Saturday: 10 AM - 2 PM

It is a highly efficient food and beverage processing technique that uses high-voltage pulses to inactivate microorganisms. It allows for a longer shelf life and improved nutritional value.

Electropasteurization and electroporation offer enormous advantages in food processing: they extend product shelf life, dramatically increase juice and oil extraction, preserve pigments, antioxidants, and essential vitamins, and significantly reduce energy consumption, production time, and space requirements. Pulsed electric fields optimize processes and are the new standard for efficiency in the industry.

Ionic Pulse Technology

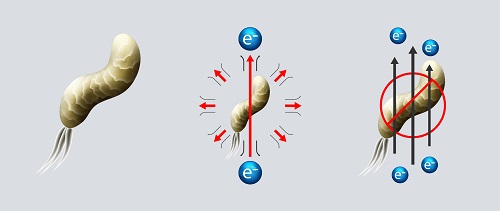

Electroporation is a technology that uses high-intensity electrical pulses to increase the permeability of cell membranes. This phenomenon allows molecules, such as water, nutrients, or bioactive compounds, to enter or exit cells in a controlled manner.

In food processing, electroporation is used to:

It is an innovative technology that reduces costs and improves efficiency, becoming a standard in the food industry.

Increased compound extraction: Significantly increases the yield in the extraction of juices, essential oils and bioactives, improving process efficiency.

Nutrient and quality preservation: Preserves antioxidants, vitamins, pigments and other essential compounds, maintaining the nutritional and sensory value of the product.

Reduced heat usage: Minimizes exposure to high temperatures, preventing the degradation of natural flavors, colors, and textures.

Extended shelf life: Reduces microbial load without affecting freshness, prolonging food preservation without the need for artificial preservatives.

Lower energy consumption: Compared to thermal processes, electroporation optimizes energy use, reducing operating costs and environmental impact.

Improved texture and structure: Facilitates the softening of fruits and vegetables, improving their processability in cutting and dehydration.

This technology represents a revolution in food processing, offering efficiency, sustainability, and higher quality in production.

Ionic Pulse Technology

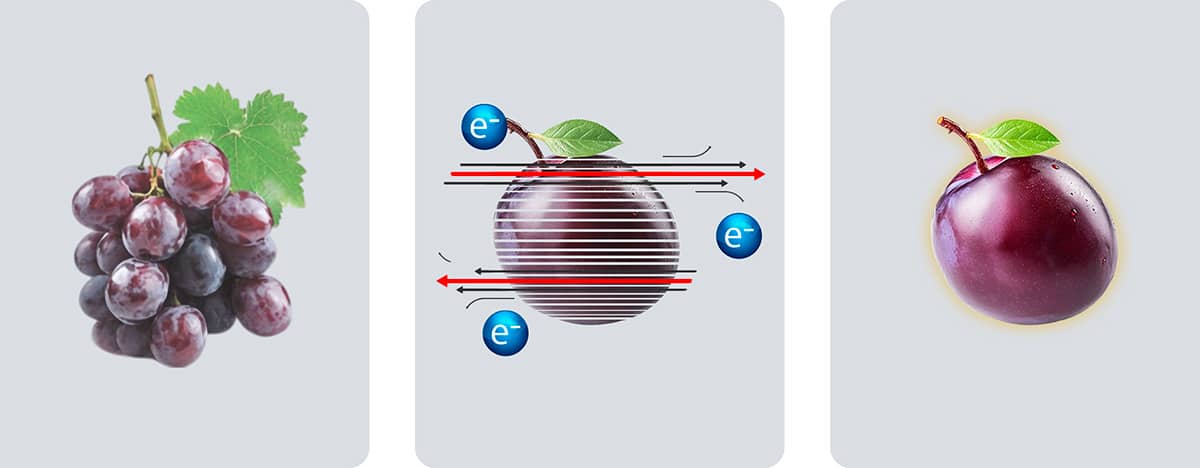

Electropasteurization is an innovative technology that uses Pulsed Electric Fields (PEF) to inactivate microorganisms in food without the need for high temperatures.

High-intensity electrical pulses are applied to a liquid or semi-liquid food, damaging the cell membranes of bacteria, yeasts, and molds, resulting in their elimination without affecting the product’s quality.

Longer shelf life without affecting quality: Inactivates microorganisms without altering the flavor, color, aroma or texture of the product.

Preservation of essential nutrients: Maintains vitamins, antioxidants and bioactive compounds that are often degraded by traditional thermal methods.

Reduced energy consumption: Requires less energy than conventional pasteurization, reducing operating costs and environmental impact.

Faster and more efficient processing: No long heating and cooling times required, speeding up production and increasing processing capacity.

Less use of additives and preservatives: By eliminating pathogens without resorting to additional chemicals, we can offer more natural and healthier products.

Versatility in application: It can be used in juices, dairy products, vegetable drinks, sauces and other liquid or semi-liquid products.

Electropasteurization is the future of food processing: more efficient, sustainable, and aligned with the demands of the modern market.