Address

Miami, FL

Work Hours

Monday to Friday: 9 AM - 5 PM

Saturday: 10 AM - 2 PM

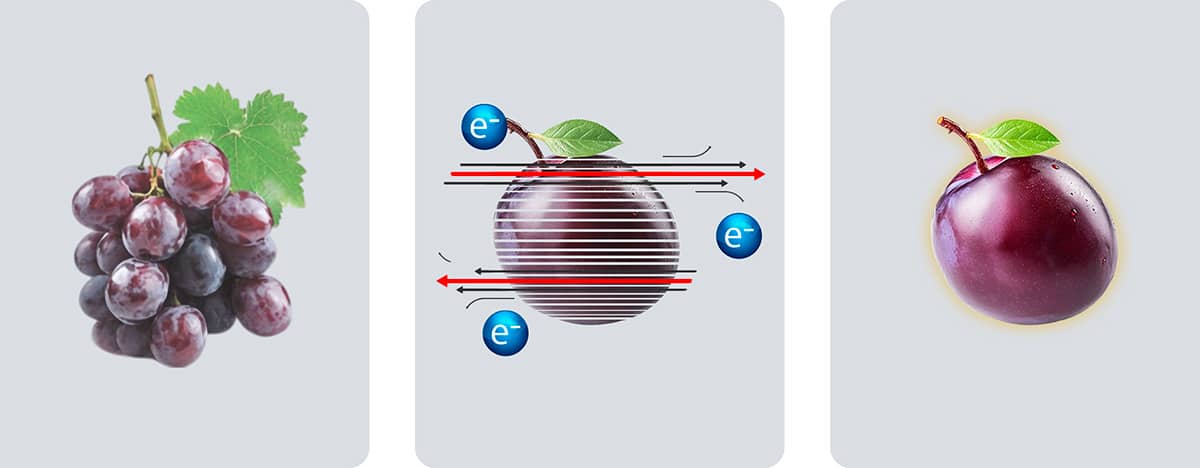

Ionic Pulse Technology

Electroporation perforates the cell membrane; the process is gentle, fast, and clean. The electrons create invisible pores in fruits, vegetables, and meats.

There are no significant decreases in the content of health-promoting compounds.

It consumes up to 9 times less energy throughout the entire process.

Significantly faster, achieving a greater quantity of product.

PEF pasteurization is regulated and accepted by the FDA (21 C.F.R. 120).

It can be used for liquid and semi-solid products: soups, liquid eggs or fruit juices.

More environmentally friendly technology.

Electroporation

Electroporation improves the extraction of aromatic and phenolic compounds in wine, resulting in a higher-quality final product. Furthermore, this process reduces maceration time, optimizing production. With electroporation, producers can offer wines with more intense and fresh flavors.

Electroporation

Electroporation optimizes the olive oil extraction process, ensuring greater quality and purity. This innovative method preserves the beneficial compounds in the oil, enhancing its flavor and aroma.

increase in oil extraction.